Turbine flaw detectors used by smelters are a type of device similar to metal detectors that can automatically check for metal body damage. As the metal rod through the coil due to changes in permeability (when the metal eddy current), so the impedance changes. Depending on whether the metal is damaged or not, there is a slight difference in this impedance. Flaw detector is the instrument to detect this difference.

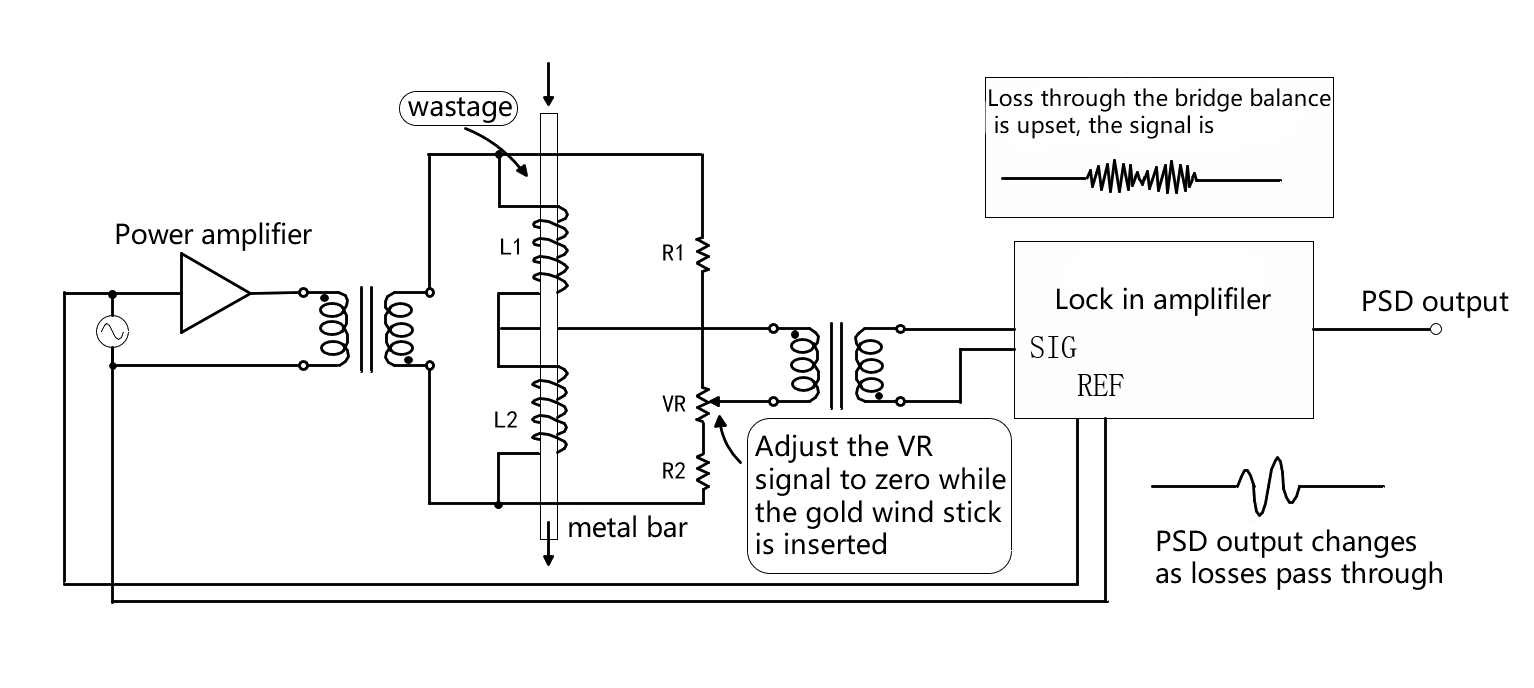

Figure 1 is a block diagram of eddy current flaw detector. The bridge is balanced when the impedance of the two terminals of the sensor is equal and no signal appears at the output. When the metal body is damaged somewhere, the impedance balance is destroyed, the output end of the signal.

Fig.1 Eddy current flaw detector

Because the metal rod passes through the two coils continuously, there are two signals output when the damaged part passes through. In practice, however, as with metal detectors, the amplitude of the signal output is so small that it is difficult to distinguish it from the bridge's leakage signal. Therefore, it is necessary to adjust the phase so that the PSD output without damage is 0, so as to be able to capture the small change in phase when the damage passes through. Eddy current flaw detector also uses a phase-locked amplifier to detect the small change in the transmission function.